Purified Water Storage and Distribution Systems play a crucial role in various industries, particularly in pharmaceuticals, healthcare, and food production. These systems are designed to ensure the safe and efficient storage, handling, and distribution of purified water, which is essential for manufacturing processes, laboratory experiments, and critical applications where water quality is paramount.

Design and Components

The design of a purified water storage and distribution system is based on specific industry standards and regulations. Key components of these systems include:

Storage Tanks: Typically constructed from stainless steel or other suitable materials, storage tanks are designed to hold purified water under controlled conditions. The tanks are equipped with features to prevent contamination, such as sealed lids and ventilation systems.

Distribution Pumps: These pumps ensure that purified water is delivered at the required pressure and flow rate to various points of use. They are designed for reliability and efficiency, often featuring variable speed drives to optimize energy consumption.

Piping Systems: The piping used in these systems must be smooth, non-reactive, and designed to minimize biofilm formation. Materials like stainless steel or high-density polyethylene (HDPE) are commonly used to ensure the integrity of the water supply.

Control Systems: Automation and control systems play a vital role in monitoring and managing the storage and distribution of purified water. These systems include sensors for flow, temperature, and pressure, along with automated valves and control panels that ensure efficient operation.

Quality Assurance

Maintaining water quality is a primary concern in the storage and distribution of purified water. Regular monitoring and testing are essential to detect any contaminants or changes in water quality. This is achieved through:

Microbial Testing: Routine sampling and analysis for microbial contaminants are essential to ensure the water remains free from pathogens.

Chemical Analysis: Testing for chemical contaminants, such as heavy metals or residual disinfectants, is performed to confirm compliance with industry standards.

System Validation: A comprehensive validation process is conducted to confirm that the storage and distribution system consistently delivers purified water meeting specified quality standards.

Regulatory Compliance

Purified water systems must adhere to strict regulatory requirements set forth by organizations such as the U.S. Pharmacopeia (USP) and the European Medicines Agency (EMA). These regulations dictate the design, operation, and maintenance of purified water systems, ensuring they meet the highest quality and safety standards.

Conclusion

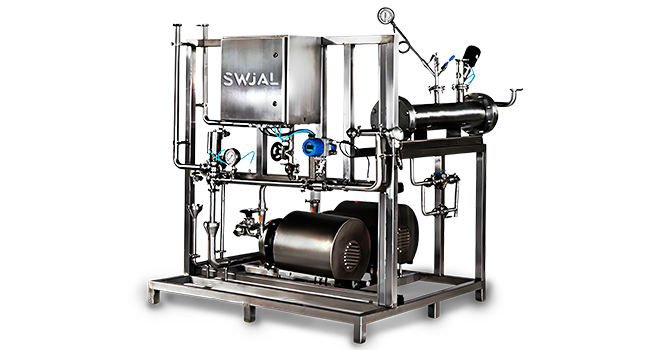

SWJAL PROCESS Pvt. Ltd. is a leading manufacturer of Purified Water Storage and Distribution Plant Manufacturers in Mumbai, India, providing tailored solutions to meet the specific needs of various industries. A well-designed Purified Water Storage and Distribution System is essential for ensuring the availability of high-quality water in critical applications. By focusing on quality assurance, regulatory compliance, and efficient design, industries can effectively meet their water needs while safeguarding public health and maintaining product integrity.

No comments:

Post a Comment