A DM (Demineralization) Water Plant is an essential piece of equipment in industries that require ultrapure water, such as pharmaceuticals, electronics, and power generation. The DM water plant operates through the principle of ion exchange, removing dissolved salts and minerals from raw water to achieve demineralized or deionized water, which has a very low conductivity and is free from contaminants. This article provides a step-by-step guide to understanding how a DM water plant works.

Step 1: Pre-Treatment of Raw Water

Before the demineralization process begins, the raw water needs to be pre-treated to remove suspended solids, organic matter, and other impurities. This step ensures that the ion exchange process is efficient and that the ion exchange resins are not clogged or damaged by larger particles. Pre-treatment typically involves:

Filtration: Water passes through sand filters or multimedia filters to remove suspended solids like dirt, sand, and silt. This ensures that the water entering the DM plant is free from physical impurities.

Activated Carbon Filtration: In some systems, an activated carbon filter is used to remove organic impurities, chlorine, and other chemicals that could damage the ion exchange resins.

Water Softening: Depending on the hardness of the raw water, a softener may be used to remove calcium and magnesium ions, preventing scaling and prolonging the life of the ion exchange resins.

Step 2: Ion Exchange Process – Cation and Anion Exchange

The core of the DM water plant is the ion exchange process, which occurs in two main steps: cation exchange and anion exchange.

Cation Exchange

In this stage, the raw water is passed through a cation exchange column containing cation exchange resins. These resins have a negative charge and attract positively charged ions like calcium (Ca²⁺), magnesium (Mg²⁺), sodium (Na⁺), and other cations present in the water.

The resins exchange hydrogen ions (H⁺) for the positively charged cations in the water. As a result, the water leaving the cation exchange unit is free from positively charged ions but contains an equivalent amount of hydrogen ions (H⁺), making it acidic.

Chemical Reaction Example:

2Na++2H+(Resin)→2Na(Resin)+2H+2Na + +2H + (Resin)→2Na(Resin)+2H +

Anion Exchange

The water from the cation exchange unit is then passed through an anion exchange column containing anion exchange resins. These resins have a positive charge and attract negatively charged ions like chloride (Cl⁻), sulfate (SO₄²⁻), nitrate (NO₃⁻), and bicarbonate (HCO₃⁻) from the water.

The anion exchange resins release hydroxide ions (OH⁻) in exchange for the negatively charged ions in the water.

When the hydrogen ions (H⁺) from the cation exchange process combine with the hydroxide ions (OH⁻) from the anion exchange process, they form pure water (H₂O).

Chemical Reaction Example:

2Cl−+2OH−(Resin)→2Cl(Resin)+2OH−2Cl − +2OH − (Resin)→2Cl(Resin)+2OH −

The result of the cation and anion exchange process is demineralized water with a very low conductivity, free from dissolved salts and minerals.

Step 3: Regeneration of Ion Exchange Resins

Over time, the ion exchange resins become saturated with the exchanged ions (cations or anions) and lose their effectiveness. To restore their ion exchange capacity, the resins must be regenerated. Regeneration is an essential step in maintaining the efficiency and longevity of the DM water plant.

Cation Resin Regeneration:

The cation exchange resins are regenerated using an acidic solution, typically sulfuric acid (H₂SO₄) or hydrochloric acid (HCl). The acid displaces the cations (calcium, magnesium, sodium) from the resin, replacing them with hydrogen ions (H⁺), which restores the resin's ion exchange capacity.

Anion Resin Regeneration:

The anion exchange resins are regenerated using an alkaline solution, usually sodium hydroxide (NaOH). The hydroxide ions (OH⁻) in the sodium hydroxide displace the anions (chloride, sulfate, nitrate) from the resin, restoring its ability to exchange anions in the water.

Regeneration Process Summary:

The resin beds are flushed with the regenerating solution, followed by a rinse with clean water to remove any residual acid or alkali. Once the resins are regenerated, the DM water plant can continue producing demineralized water.

Step 4: Mixed-Bed Polishing (Optional)

In some applications, especially in industries like pharmaceuticals or electronics where ultra-pure water is required, a mixed-bed ion exchange unit may be used as a final polishing step. A mixed-bed unit contains both cation and anion exchange resins mixed together in a single vessel, providing a higher level of demineralization.

The water from the cation and anion exchange units is passed through the mixed-bed unit to remove any remaining traces of dissolved ions. This results in water with an extremely low conductivity, ideal for applications that demand the highest purity standards.

Step 5: Conductivity Monitoring and Quality Control

Throughout the demineralization process, the quality of the water is continuously monitored using conductivity meters. Conductivity is a measure of the water's ability to conduct electricity, which is directly related to the concentration of dissolved ions in the water. The lower the conductivity, the purer the water.

In a well-maintained DM water plant, the conductivity of the demineralized water should be extremely low, typically below 1 microsiemens per centimeter (µS/cm), depending on the application. Regular monitoring ensures that the DM water plant is operating efficiently and producing water that meets the required purity standards.

Step 6: Storage and Distribution

Once the water has been demineralized, it is typically stored in a storage tank made of materials that prevent contamination, such as stainless steel or plastic. The demineralized water is then distributed to the points of use through a network of pipes or pumps, depending on the specific requirements of the facility.

Key Features of a DM Water Plant

Efficient Ion Exchange: The cation and anion exchange units effectively remove dissolved salts and minerals from the water, ensuring high purity.

Regeneration System: Regular regeneration of the ion exchange resins ensures that the plant operates efficiently and provides consistent water quality.

Low Conductivity Water: The resulting demineralized water has a very low conductivity, making it suitable for sensitive industrial applications.

Scalability: DM water plants can be designed to meet the specific capacity and purity requirements of different industries, from small laboratories to large manufacturing facilities.

Conclusion

A DM water plant operates through a series of well-defined steps, starting with pre-treatment and progressing through ion exchange and resin regeneration. This process results in high-purity, demineralized water that meets the stringent requirements of industries like pharmaceuticals, power generation, and electronics. The ability to consistently produce water with low conductivity makes DM water plants essential for operations that demand ultra-pure water.

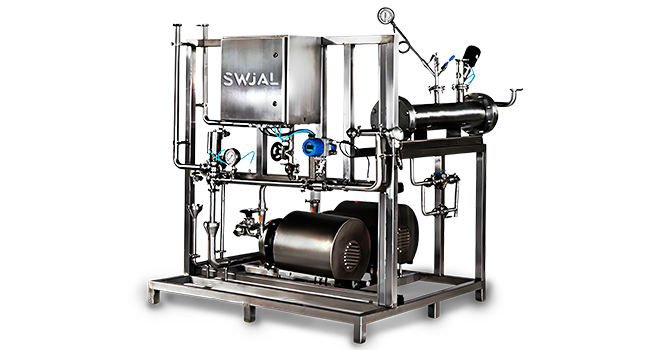

For reliable and advanced DM Water Plant solutions, SWJAL PROCESS is a leading manufacturer in Mumbai, India, offering cutting-edge technology and expertise to meet industrial water purification needs.