In industries requiring sterile environments, the role of clean steam generators is indispensable. These systems are designed to produce steam free from impurities, ensuring compliance with stringent quality and safety standards. Applications in the pharmaceutical, food, and biotech sectors rely heavily on clean steam to maintain the integrity of their processes and products.

The production of clean steam is achieved by utilizing purified water, such as demineralized or distilled water, as the feed source. Through the process, contaminants like minerals, microbes, and endotoxins are effectively removed. This ensures that the generated steam meets the strict specifications required for use in sterilization, humidification, and other critical applications.

|

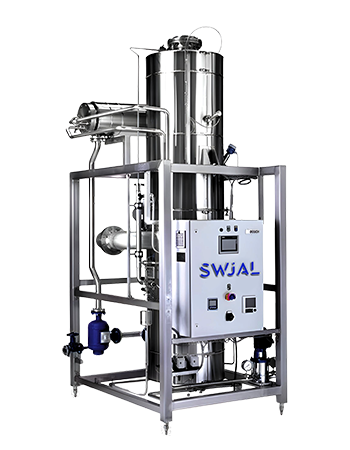

| Pure Steam Generator for Pharmaceutial Manufacturing |

Applications and Importance

The importance of clean steam in sensitive environments cannot be overstated. In pharmaceutical manufacturing, it is used for sterilizing equipment, vessels, and piping systems. Clean steam also plays a crucial role in autoclaves, where it ensures that medical tools and devices are sterilized effectively. In the food and beverage industry, it is used to ensure the safety and quality of consumable products by preventing contamination during processing.

Clean steam is critical in maintaining a sterile environment, particularly in biotechnology labs and hospitals. By eliminating impurities, clean steam minimizes the risk of contamination, thereby safeguarding products, processes, and human health. The high purity level of clean steam also ensures compliance with global standards such as ISO 22000 and cGMP guidelines.

Key Features

Modern clean steam generators are equipped with advanced features to enhance efficiency and reliability. Systems are constructed with corrosion-resistant materials, such as stainless steel, to maintain the purity of the steam and extend the equipment’s lifespan. Automatic control systems are often integrated to ensure precise temperature and pressure regulation, improving operational efficiency.

The compact design of these systems allows for easy installation and maintenance. With energy efficiency in focus, clean steam generators are engineered to reduce water and power consumption, making them sustainable and cost-effective solutions for various industries. The use of heat exchangers and double-tube sheet designs ensures complete separation of the heating medium from the purified water, further enhancing steam quality.

Types of Clean Steam Generators

Clean steam generators are categorized based on their operating mechanisms and applications. The most common types include electric, gas-fired, and steam-to-steam generators. Electric steam generators are preferred in facilities requiring precise control over steam quality and output. Gas-fired units, on the other hand, are widely used for large-scale operations due to their high capacity and efficiency.

Steam-to-steam generators utilize plant steam as the primary energy source to produce clean steam. These systems are ideal for facilities where plant steam is readily available but does not meet purity standards. Each type of generator is designed to cater to specific operational needs, ensuring that industries can choose systems aligned with their requirements.

Benefits

The use of clean steam generators offers numerous benefits across industries. Enhanced product quality is achieved by eliminating risks associated with contamination. The equipment also ensures regulatory compliance, helping businesses avoid penalties and maintain certifications. By using purified water, operational costs are reduced due to the extended lifespan of equipment and minimal downtime.

Energy-efficient designs contribute to reduced utility expenses while promoting sustainability. The ability to produce high-quality steam consistently allows businesses to maintain the integrity of their operations, fostering trust and reliability among customers and stakeholders.

Factors to Consider When Selecting

It is essential to consider factors such as capacity, material construction, and energy efficiency. The generator must be capable of meeting the specific steam demands of the facility. The choice of materials should prioritize corrosion resistance and durability, ensuring long-term reliability. Additionally, systems with advanced automation and monitoring features provide enhanced control and safety.

Maintenance requirements and after-sales support are critical aspects that should not be overlooked. Choosing a manufacturer that offers comprehensive support services ensures that the system operates optimally throughout its lifespan. Proper planning and assessment of operational needs will help in selecting a clean steam generator that aligns with business objectives.

Conclusion

Clean steam generators are indispensable for industries where sterility and high-quality standards are paramount. These systems ensure safe, efficient, and sustainable operations by producing pure steam free from contaminants. Their applications span a wide range of industries, including pharmaceuticals, biotechnology, food processing, and healthcare, highlighting their versatility and importance.

For state-of-the-art clean steam generator systems, Swjal Process is a leading manufacturer in India, offering innovative solutions tailored to industry needs. Their commitment to quality and excellence ensures that businesses can achieve superior performance and compliance with global standards.